|

|

|

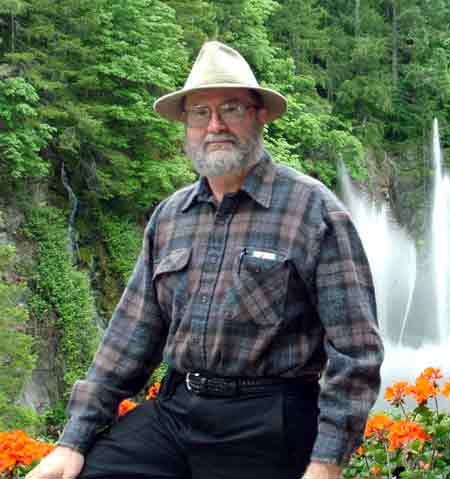

Tanfoglio GT27/FIE-Titan 25acp (7E)

|

| |

|

Quantity in Basket:

None

Code: FIE_7E

Price: $68.00

Shipping Weight: 0.20 pounds

|

| |

This is a set of smooth grips for the 25 ACP pocket pistol

made by Tanfoglio. There were also 22 Short versions. Originals imported as finished products

from Italy, before the 1986 gun control act, had steel frames

and slides. Then, EXCAM (a Florida-based importer) brought

in the components such as the slide but manufactured an aluminum

lower component or frame. These are marked "Excam" on the

barrel and re-stamped on the slide along with the Tanfoglio

and GT-27 original markings. After a time, Excam ceased

production and import of parts.

Finally, Firearms Import Export company, or FIE, began

bringing in components from Tanfoglio and manufacturing

the frame from a zinc alloy which is usually referred to

as "pot metal". It has fairly low strength and low resistance

to wear and galling compared to steel, but can be more

easily cast at lower cost than aluminum. But these latter

versions of the GT-27, known as the FIE TITAN, developed

a somewhat lower quality reputation than the two previous

incarnations (which, generally, were reliable guns).

In any case, these grips should work with any of the three

versions regardless of the name. All were basically the

same as the Tanfoglio except for the frame material and

worksmanship or method of production. The gun is similar in

some ways to a tip-barrel Beretta but the barrel does not

tip. This is an exposed hammer pistol, with a half-cock

notch, and while not quite up to the firing-pin block

safety standards of modern pistols, is fairly robust as

far as not going off when it isn't supposed to. The hammer

has to fall to strike the firing pin, so sear tip breakage

would have to occur with the hammer cocked fully for an

accidental discharge to take place, or else the gun would

have to be dropped on the hammer, snapping the sear so that

the hammer could be driven against the firing pin hard

enough to fire the cartridge...less likely than with the

Browning/Colt 1903, 1908 and 1910 models using spring loaded

striker held by the sear only, and all the safety machanisms

being solely to prevent movement of the sear. Failure of

the tip of the small sear would release the striker, no

matter if the safeties were all functioning, in those designs.

In any case, here are the grip dimensions:

- Width across the top flat area of the right grip = 1.4 inches

- Width across the top flat area of the left grip = 1.1 inches

- Length of front edge, right grip = 2.4 inches

- (Left grip front edge is full of curves)

- Width across widest part of the base parallel to flat bottom = 1.5 inches

- Height of screw hole center from flat base = 1.2 inches

- Width of right grip across screw hole = 1.4 inches

- Width across widest part of left grip = 1.65 inches

- Overall height of both grips 90-degrees to flat top = 2.4 inches

- Widest part of right grip near top = 1.5 inches

Please note: You can select two different mounting

methods. The grip frames generally are threaded and

use two separate screws with about .365 total length

including a 0.106 thick head, which fits into a .278 hole

diameter, with the thread passing through a 0.121 hole

in the grip. This is the same basic hole found in a thick

1911 Colt grip other than the lack of a 1/4-inch hole for

the mounting stud.

Please note: You can select two different mounting

methods. The grip frames generally are threaded and

use two separate screws with about .365 total length

including a 0.106 thick head, which fits into a .278 hole

diameter, with the thread passing through a 0.121 hole

in the grip. This is the same basic hole found in a thick

1911 Colt grip other than the lack of a 1/4-inch hole for

the mounting stud.

However, if you prefer, I can provide two 5-40 x 1/4 inch

fillister head screws, with a much smaller hole for the

head diameter. If you have lost the original screws or

if they are damaged, the new stainless steel screws will

work fine and look nice. BUT you cannot use the original

screws if you elect to have the holes made for the smaller

fillister head screws, without enlarging the hole for the

countersunk portion (the head). Default is to use the

5-40 x 1/4 screws.

Just click the option you want, above. If you leave it

as shown, the grips will have the holes sized for two

new 5-40 x 1/4 fillisters and the screws will be provided. If you select the optional factory holes

instead, then you won't be able to install the 2-56 kit

later because those holes are too large.

These grips are prevented from moving about the screw

by a pin that passes through the frame and projects a little

on either side. You simply "paint" the tip of the pin

with a Magic marker and press the grips against the gun,

with the screw in place. A dot on the back of the grip

then is transferred, and you make a small, shallow hole

with a hand-turned drill bit or a little Moto-Tool bit

where the dot indicates. If you get it too large or off

the right position, you can fill it with a drop of epoxy

glue, let it harden, and try again. If you wipe some

Vasoline on the gun frame, you can even use the not-quite-

hard epoxy as a mold, pressing the grip on the gun before

the glue is completely firm, so the pin makes its own

hole.

Another good method is to mark the cut-out in the frame

with the grip temporarily mounted (use a pencil through

the frame from the other side). Then remove the grip,

and put a small pin or screw hole in the grip near this

line, so that the pin or head of the screw will bear

against the frame edge and keep the grip from turning.

|

|

Please note: You can select two different mounting methods. The grip frames generally are threaded and use two separate screws with about .365 total length including a 0.106 thick head, which fits into a .278 hole diameter, with the thread passing through a 0.121 hole in the grip. This is the same basic hole found in a thick 1911 Colt grip other than the lack of a 1/4-inch hole for the mounting stud.